- Well Drilling

- Drinking Water for Your Home Drinking Water for Your Mobile Home Free Water for Your Irrigation and Garden Free Water for Commercial Irrigation Systems Keep Your Pond Full Public Water Systems

- Water Treatment

- Remove Iron and Sulfur with NO MAINTENANCE! Quick and Easy to Use Chlorination Systems U-V Light Disinfection Systems Water Softeners Whole House Reverse-Osmosis Systems (R/O) Aeration Systems Links to Related Sites/Products We Sell

Need To Know Information

Three Things Everyone Should Know About Their Water Well System |

||

|

|

Here I explain the 3 basic aspects of having a dependable and safe water well system. If you're considering having a water well system installed for drinking or irrigation this would be the first thing to read. Then you can read more detailed information concerning maintaining your system and keeping your water safe in the other sections of our web site. Thank You for Visiting! Let's assume that you fall into one of the following categories:

You can use these three suggestions as a guide and then read more about maintaining your system, water treatment, and sanitation throughout this web site. You can also see a number of examples of our work in each of these areas. Any other questions you have about site location, water quality, testing, and treatment are almost certainly answered on the following web site. I have a number of excellent web sites linked at the bottom of this page. When it comes to water quality or potability they all pretty much say the same thing. That is, the homeowner is responsible for making sure that his or her water is safe for consumption and steps need to be taken to guarantee that your water is bacteria free and safe for your family. It's really not that complicated and doesn't take a lot of time or effort to keep your equipment in good condition and have good quality, safe, and healthy water in your home. It does take an initial investment for the right equipment to get started. Fortunately, technology has caught up with our industry. Costs have come down and today water treatment equipment works like it should with little or no maintenance. So let's get started. It doesn't matter if you have an above ground pump or a cased well with a submersible pump like the two systems pictured here. CDC – Private Ground Water Wells Home Page 1) The well and pumping system must be in good condition and deliver an adequate flow of clear water with no sand and no salt.

2) If your well water has iron content that causes staining or hydrogen sulfide gas that causes a sulfur smell then you need to install a Watts Filox media filter.

The NF-10 will sufficiently remove the iron and sulfur content and eliminate the staining and odor. It will also filter the water to 20 microns and remove substantial amounts of manganese, chlorine, and other minor mineral content. By removing this mineral content it usually softens the water adequately so that additional water conditioning (softening) is not needed. In some cases other water conditioning may be required. 3) A. It is important to chlorinate your well, home plumbing, and fixtures periodically to safeguard against bacteriological contamination. B. It is ideal to install a final ultraviolet light disinfection system.

|

|

|

|

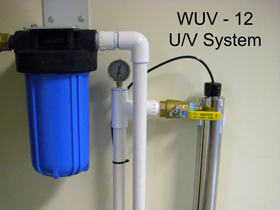

That sure seems like a lot more than three things. Well, maybe Three Basic Things! The WUV-12 U/V disinfection system pictured here (Figure 4) is excellent for water systems that already have a Watts Filox media filter installed. These units are simple and smart. The HydroSafe disinfection system pictured here (Figure 5) is an outstanding value and is excellent for water systems with or without other filtration. It serves a triple purpose. It has a replaceable activated carbon 0.2 micron cartridge filter that captures sub-micron particles and it provides ultraviolet protection. This is one of the best water conditioning units to come out in some time. We will be glad to help get your water system up to speed. Call for free advice and to discuss pricing. These systems are engineered for a lifetime of service (literally) with minimal maintenance and we install them at costs that are less than we charged 10 years ago. It's a good value considering the benefit. |

|

Keeping Your Water Well System Working Properly |

||

Regular MaintenanceThe water well that we install(ed) at your home should last for many generations. The pump should last for many years (as long as 30 years or more) if you follow this good advice. 1) Cleaning - Keep the area around your pump, tank, or well casing clean and free of dust, sand, weeds, and spider webs. On above ground pumps dust, sand, and spider webs are drawn into the motor as the motor intakes air for cooling. This gets into the motor bearings and will eventually cause the pump motor to fail. If your pump is in a garage or walk-in pump house use a shop-vac with a brush to clean around the pump occasionally. If your pump and tank are outside hose them off with the water hose and wipe them down occasionally. Put plastic and rock down around the pump and tank or pour a cement slab to help keep the area clean. 2) Ventilation – Keep above ground pumps well ventilated during warm weather. Never wrap anything around the pump motor that will block the intake vents. If your pump is in a pump house make sure the pump house has good cross-ventilation so the motor gets plenty of air. The same applies to deep well casings, pressure switches, and tanks. Make sure the tank and pressure switch are not enclosed in a humid pump cover, pump house, or location where they stay wet and/or humid all the time and will rust. 3) Freeze Protection – Do not allow the pump or plumbing at the pump to freeze! ALLOWING THE WATER TO "TRICKLE" INSIDE YOUR HOME WILL NOT NECESSERAILY PREVENT THE PUMP OR PLUMBING FROM FREEZING. This applies to cased wells with submersible pumps and wells with above ground pumps. Water does not flow through the pressure switch. The pump, pressure switch, gauge, and plumbing can still be damaged by freezing even if you leave the water running. And leaving the water running causes your pump to "cycle" on and off the entire time that the water is trickling. This puts a lot of extra wear on the pump motor and runs your power bill up. The same thing applies to a well built, insulated pump house. A well sealed pump house will help to hold some heat from the ground but if it gets cold enough the pump will still freeze and break inside the pump house. It is important to have some source of heat, such as a 75 watt flood lamp bulb, to add a small amount of heat. The best thing to do is to cover your pump (or deep well pressure switch) and plumbing with a thick sheet of plastic and put the lamp under the plastic. It's not even necessary to cover the entire tank. The tank will not break. We installed the well and pump that you see picture here in the old pump house sometime around 1995 where it sat, literally untouched , until the winter of 2009 when it froze and the ceramic seal broke. Since it was a Gould's J+ pump it was worth tearing the pump down and replacing the seal. While I was at it I cleaned and painted both the pump and tank. I left it with this plastic and a lamp so it would not freeze again. It should go for another 15 years or more. Just drape the plastic over the pump and all the pipes. Make sure that the plastic is all the way down to the ground (covering the pipe leading to the tank) and put bricks or something on it to make sure it's sealed up and won't blow off if it's exposed to wind. Now you're heating only a few square feet under the plastic and not trying to heat the entire pump house with a light bulb. Do this inside the pump house even if you have a nice pump house. Some people use a small fan-forced heater if they are heating the whole pump house. The 75 watt flood light would certainly be a lot less expensive and safer. Make sure the lamp does not touch the plastic and is positioned safely so it does not come in contact with anything that would burn. A lamp fixture with a metal shade is safest. When it warms up don't forget to remove the plastic so the pump gets plenty of fresh air during the warm months. Protect pipes under your home or out in the yard with heat strips and insulation if necessary. In the links below you will find a link to a merchant that sells wireless remote switches and heat strips. These can also be purchased at Walmart, Lowes, and Home Depot. You can plug a wall receiver into a 110v. outlet and then plug the lamp into the receiver. You can then use a wireless remote to cut the lamp on and off without walking out to the pump house. If you left a 75 watt bulb running from November to March it would still cost less than a dollar so just leave it on if you're likely to forget. << In the example at the left you see what can happen if you allow the pump to freeze. This one broke the motor bracket and when this happens I just throw the pump away and install a new one. It's a very expensive mistake. This system had been here for a long time and the owner had not even invested the time to level around the pump or build any type of pump enclosure as it was explained in great detail to him. There was a plastic storage area behind the pump that should have been built around the pump instead. It doesn't take a lot of effort to prevent this. DON'T LET YOUR PUMP OR PIPES FREEZE! Protect your water treatment equipment the same way if it is subjected to freezing weather. You can cover the top of the unit and plumbing with a large plastic bag and put a mechanic's light or some other type of lamp under the plastic bag. Make sure the lamp does not come in contact with the plastic or the pipes. 4) Rust Protection – After a period of months (or years if your pump is in a good location) and the pump and/or tank begin to rust, wire brush the pump and lightly sandpaper the tank. Spray a good coat of primer then top coat paint on both. Tape off the pipe fittings for a neat job. If you use Rustoleum this will probably be a better paint job than the manufacturer did and will last for years. TAKING CARE OF YOUR WATER WELL EQUIPMENT TAKES ONLY A FEW MINUTES AND WILL SAVE ON UNNECESSARY REPAIRS AND ELIMINATE THE INCONVIENIENCE OF BEING OUT OF WATER! |

||

Above Ground Pump |

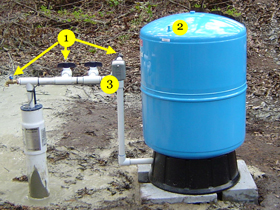

Checking the Tank Pressure and Pressure SwitchHere's what you need to know to check and adjust the air pressure in the tank and the pressure switch settings ON RESIDENTIAL SYSTEMS. This is the most important thing but few people understand how to do this. Apparently this includes a lot of the other well drillers since we see these all the time that were never set correctly. Most of the pumps that we replace, especially submersible pumps, are the result of a bad tank and/or an improperly adjusted pressure switch. If either of these settings are incorrect the pump can "cycle" on and off continuously or more frequently than it should. This causes a lot of extra power consumption (running up your power bill) and puts a lot of wear on the pump. This usually results in a burned-out pump and an expensive repair. This is not rocket science but DO NOT ATTEMPT TO WORK ON THE PRESSURE SWITCH OR ANY ELECTRICAL COMPONENT IF YOU DO NOT HAVE GOOD BASIC KNOWLEDGE OF ELECTRICAL SYSTEMS AND GOOD GENERAL MECHANICAL APPTITUDE. Instead, call us for service on your water system or water treatment system. First, read the section above about cleaning around your equipment and do that. Make sure there are no chemicals, oil, paint, or pesticides stored around your water well equipment and clear the area of any overgrowth or trash. 1) There must be a spigot, water pressure gauge, and cut off valve at the pump or top of the well casing. (see figure 1) If there is not, then you have some plumbing to do or you should call us for service. The tank must never be isolated from the pump by a ball valve. Notice that the pipe runs from the pump to the tank and the cut-off valve is after a "T". So when the cut-off valve is closed water would still pass freely between the pump and tank. If you don't have a water pressure gauge then you can't set anything. The water pressure gauge and hose bib (spigot) are between the pump and tank so they would work when the ball valve is off. 2) If the power is on and the pump has been working then cut the valve going to the house off and connect a short water hose (with no kinks) to the spigot and open it fully. Look at the pressure gauge to see how much pressure the pump is running at when the spigot is running fully open. A good water well system will run the hose wide open at good pressure. A less productive well would be running at 10-20 psi and a good productive well would be running the spigot at 40 psi or more. Using a watch, you can capture and measure the water in a 5 gallon bucket or graduated mop pail so you will have an idea of the gallons per minute (gpm) your pump is yielding. Then you'll know if I ask later. If you have an above ground pump you can hear the pump running. If you have a sub you might have to put your hand on the pipe at the well casing to feel the pump running or you might hear it vibrating. Listen and watch for a couple of minutes. If the pump is cutting on and off then the pressure switch has been set to low and the pump is cycling. Close the spigot and watch the pressure gauge. The pump should build pressure and shut off. This is the "cut-off" pressure and is determined by the setting on the pressure switch. What we often find is that some guy (or well driller/repairman) replaced the pressure switch a while back and just left it at the factory 40psi setting. So when there should have been 80psi of pressure in the house his pump has been "cycling" on and off between 20 and 40psi. The pressure in the house has been terrible and the pump has been under a tremendous amount of stress. If you walk up to a well system and there is no gauge then the previous installer/repairman was a slacker. You can't adjust any of these settings without a pressure gauge. 3) First, let's make sure there is some air pressure in the tank. Cut the power off to the pump. Open the spigot and let all of the water pressure off. The water pressure gauge should drop to 0. Find the air valve on the diaphragm tank. This is usually on the top. (see figure 2) If you have a horizontal tank it may be on the end. It's just like the air valve on your car tires. If you have a galvanized tank call us for advice. There are some different considerations with galvanized tanks. Make sure there is at least 15 pounds of air pressure in the tank. If the air pressure is at 0 and the tank feels full of water it is probably bad. When all of the water pressure is drained of the system the tank should be light. If the pressure was 0 or low then use a compressor and fill it up to at least 15 psi. If the tank holds pressure then proceed to the next step. We'll put the proper amount of air in the tank after we check the pressure switch. If the tank won't maintain pressure then stop there and call us for service. |

|

| If your pump and tank look like the Above Ground Pump pictured here then you probably have a shallow well. However, we do deep wells routinely in excess of 75-100' and use above ground pumps. You can use an above ground pump anytime the water table (not the depth) of the well is 25' or less. It could also be a deep well with an old above ground packer pump. | ||

Submersible Pump |

||

If you have a tank and well casing like the Submersible Pump pictured here then you probably have a deep well. However, we can do a screened well 25' deep and use a submersible pump in a 4"casing just like this. It would appear to be a deep well but is actually a shallow well with a submersible pump. |

||

Usually, a setup like the one pictured at top would be a shallow well and the one pictured at the bottom would be a deep well. |

||

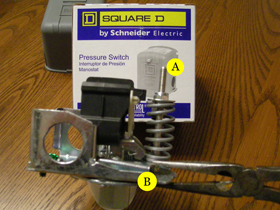

AT THIS POINT THE POWER SHOULD STILL BE OFF Read the rest of this section fully before proceeding. Locate the pressure switch and using a 3/8" nut driver (blue handle) turn the nut on the cut-off adjustment clockwise (tighten) until it is down about ¾ of the distance to the bottom. (figure A) Do not over tighten and damage it. (Note: Most good pressure switches are similar to the one shown at the left. The taller post is the cut-off adjustment. The directions are normally under the lid. Do not adjust the cut-in pressure. You may loosen it if you think someone may have adjusted it.) We've increased the cut-off setting so that now we can cut the power back on and the pump will not shut off. Make sure the spigot is closed and watch the water pressure gauge. We can now see just how much pressure the pump will build. When the pump reaches its' maximum pressure open the spigot to release the pressure and CUT THE POWER BACK OFF. DO NOT RUN THE PUMP FOR MORE THAN 1 MINUTE WITHOUT OPENING THE SPIGOT. Turn the adjustment nut counter-clockwise (loosen) about ½ of the adjustment. Cut the power back on and open the spigot until the pump is running. Close the spigot and watch for the pump to cut off. CUT THE POWER OFF and increase or decrease the tension on the spring. Cut the power back on and check the cut off pressure. Repeat this process until the pump is CUTTING OFF COMFORTABLY BELOW ITS' MAXIMUM PRESSURE or about 7 pounds below its' maximum pressure. Submersible pumps building 90psi or more pressure should not be set over 80psi OR THE PRESSURE RATING OF THE TANK. ** If you are a skilled technician, ALTERNATELY, WITH THE POWER ON and using a pair of INSULATED PLIERS, compress the plate on the bottom of the pressure switch (figure B) as illustrated and hold the switch closed until the pump reaches its' maximum pressure and then release the plate. This is a lot quicker but be sure to use insulated pliers and DO NOT TOUCH ANY OF THE ELECTRICAL PARTS OR WIRING IN THE PRESSURE SWITCH OR YOU MAY BE SHOCKED. DO NOT DO THIS IF YOU ARE WET OR STANDING IN WATER. USE EXTREME CAUTION WHEN WORKING WITH THE PRESSURE SWITCH AROUND WATER. 4) Finally, set the air in the pressure tank by cutting the power off and opening the spigot to release all of the water pressure. Now check the air pressure in the tank with your tire gauge (see figure 2) and ADJUST IT TO 3 PSI BELOW THE "CUT-IN" PRESSURE. For example, if the pump is cutting off at 60psi and on at 40psi, adjust the air pressure in the tank to 37psi. 5) Test by running a full flow of water through the hose into the ditch or garden for 30 minutes then cut the spigot off and make sure the pressure builds up and the pump cuts off properly. The pump should reach its' cut-off pressure and shut off quickly without straining and wasting power. If you fill the swimming pool and run the hose for hours (or days), when you finally shut the water off walk over to the pump and make sure it builds pressure and cuts off properly. Suppose you wired a green indicator lamp into the pressure switch and mounted it outside the pump house. You could glance over and see if the pump was running at any time. You get the point. ** If you ever notice that your water pressure is inconsistent or "surging" or if you expect any problem with your water system CUT THE POWER OFF RIGHT AWAY and call us for service or advise. ** Avoid "cycling" the pump for long periods of time. When you run water sprinklers (especially 1 at a time) check the pump to make sure it is not cutting on and off. If it is, then run two or three sprinklers at once. You're paying the same amount for electricity to run one sprinkler as you would for running 3 or 4 sprinklers at the same time. If you can run three or four sprinklers at once then do it and reduce the operating cost and wear on the pump. Drip irrigation is very likely to cycle the pump. ** The pressure switch should not come out of adjustment. Keep it clean and keep ants and insects out of it. Blow or brush it out if it gets dirty. ** You should check the tank pressure annually or more often if it is very old. Check the tank pressure if you see your water pressure doing anything unusual like surging. Use a regular tire gauge, cut the power off, and drain the water pressure first. |

||

Tips On Building (or Buying) a Good Pump House |

||

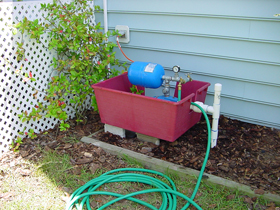

KEEP IT SIMPLE!You may get some good ideas about how you're going to protect your water well equipment by looking at these pump houses and pump covers that we and some of our customers have built or bought. You can spend a lot of time and effort or do something simpler that still protects the equipment from harsh weather and helps keep it clean. The important thing is that you make the equipment accessible and protect it from freezing. By far the best thing to do, if possible, is to locate the pump and tank in the garage or storage building. If that's not possible then build a pump cover that is light enough to remove completely if the system has to be worked on or make sure one side opens completely. In the garage or storage building (figure 2) the pump is protected from the elements. You could build a nice cabinet around it or cover it with plastic and put a lamp (with a 75 watt flood light bulb) under the plastic to protect it from freezing. Then occasionally you could vacuum around the equipment to keep it clean. |

||

Whenever possible we locate the pump and/or tank under the home or under the steps (figure 3) if a larger porch is not planned. In this situation you can easily enclose the equipment or just put lattice work around the pump. This would look nice.

|

||

If you build a pump house don’t build something that will make it difficult to get to the equipment. This nice little pump house (figure 5) is small and light enough to be flipped over on one side. It is insulated with foam board (figure 4) and has ventilation and a lamp for heat. This is a really nice pump house. Be sure and use treated lumber. You can use bricks or 4” blocks to make a good, level foundation for the pumphouse. Put plastic down on the ground for a moisture barrier and put pea gravel or rock down to keep the pump house neat and clean.

|

||

This customer did a good job building an enclosure (figure 8) to protect their investment. The water well system was installed sometime around 1998. In 2010 they had us install this Watts Filox filter and a chlorinator. They have good quality water in the home and they know it is safe and sanitary. The small room they built is well insulated. The equipment stays clean and is protected from freezing. * If you are building a pump house out in the yard where it is exposed to rain do not use batt insulation like this. (Figure 7) Instead use foam board as shown in the previous section photo. (Figure 4) |

||

This customer built a nice looking pump house. (figure 9) The door is large enough to allow plenty of access and it is well insulated. It is also wired nicely with an overhead lamp. He has rock in the bottom so he can hose the equipment right off. |

||

This well was installed sometime around 1995 for irrigation use. The owner gets an A for ingenuity for using this pet house to protect his pump. The lid is made to come right off so he can get to the pump when he needs to. I haven’t heard from the owner since then so I expect the pump is still doing its job. If well taken care of a good pump might last thirty years or more. |

||

These are great. This type of storage cabinet is easy to put together and cost much less than the materials required to build a pump house out of wood and shingles. The lid and doors open right up and allow plenty of access to the pump. In the winter you can cover your pump with plastic and use a lamp to prevent it from freezing. This particular one is not used for a pump house but I have used them numerous times. They are quick and easy to install. |

||

|

If you purchase one of these in advance we will assemble it and install it around the pump and tank at NO CHARGE. These are available at Lowes. More information » |

||

If you really want a top-of-the-line pump cover you can have us install a nice pump cover like this one (figure 14). Read more about this pump cover. This one is constructed to last for many years. |

||

Keeping Your Water Safe and Sanitary - Chlorination |

||

Periodic Chlorination is the first step in guaranteeing that your well water is safe for your family. But not many people chlorinate their home water system because they just don't know how or never knew how important it is. SC-DHEC recommends that you chlorinate your home water system at least once each year to safeguard against contamination by harmful bacteria. Chlorinating your water system also prevents mineral buildup and even algae growth that is common in home water systems without chlorinated municipal water. We custom build each chlorinator to give you a quick and easy way to chlorinate your home water system and we do this for an affordable price. Deep wells and shallow wells are chlorinated differently. View more detailed information on how this is done and to see other examples. ** Ideally, you want to install this chlorinator to use on a periodic basis in combination with a whole-house U/V system for final protection against bacteriological contamination. |

||

Ultraviolet Light Disinfection Now With Carbon Filtration! |

||

HydroSafe Water Filtration and U/V disinfection system! THIS IS AN OUTSTANDING NEW PRODUCT! The Watts Hydro-Safe filtration system is an excellent choice for your home if your well water doesn't require iron or sulfur removal or if you want to add U/V protection to you drinking water. The Hydro-Safe unit is a 3-step filtration system that has:

THIS UNIT PROVIDES OUTSTANDING FILTRATION AND PROTECTION. IT IS EASY TO INSTALL AND WE INSTALL IT FOR A VERY REASONABLE PRICE! Download the Hydro-Safe Whole House U/V – Carbon Filter brochure. |

||

|

We're proud to be the EXCLUSIVE Watts® dealer If chlorination is the first step in guaranteeing the safety of your well water then U/V protection is the last. The Watts® WUV-12 (110 or 220 volt) disinfection system is compact and has a substantial flow rate of 12 gallons per minute. It effectively kills any harmful bacteria that could infect your home water system and requires minimal servicing which takes just a few minutes and can be done by the homeowner. It’s reassuring to know that your drinking water is U/V protected and safe for your family. We install this system for a very affordable price. View one of our installations and read a more detailed explanation of how it works. |

||

Links to Product Brochures |

||

Pump Manufacturers

|

Gould's Pumps – ITT (home page) - We have been a Gould's Dealer for over 15 years. |

|

Schaefer VersaJet Pump Data Sheet - We have been a Franklin Electric/Schaefer Pumps Certified Contractor since 2008. Legend Series Submersible Pump Data Sheet |

|

Koshin America Pumps - We are an authorized factory dealer for this fantastic line of industrial pumps. Read more about them at their web site or in the Products section of this site. I can order one of these for you at an excellent price. |

Links to Affiliates and Organizations

|

Gould's Professional Dealer's Association - We have been a GPDA member for over 15 years. Watch a short video about the GPDA dealers. |

|

Learn about geo-thermal heating and cooling at WaterFurnace.com -

We are WaterFurnace® trained |

|

South Carolina Ground Water Association has some very helpful information about water wells, Frequently Asked Questions, and links to other sites. We are a member of SCGWA. |

Helpful Sites

|

Easy Street Electronics - Order wireless remote On/Off Switches here. Wireless remote switches can also be purchased at Lowes, and Home Depot. |

|

Walmart - Sells these wireless switches so you don't have to go out to the pumphouse to cut the light off. Order online only. I've purchased good ones from the store also. |

|

Lowes - You can get these heat strips at Lowes, Walmart, and Home Depot to wrap around the pump and to insulate pipes with.

|

|

|

CVS – NeverScrub Toilet Chlorinators

CVS – NeverScrub Toilet Chlorinators